The Process of Making Cheese

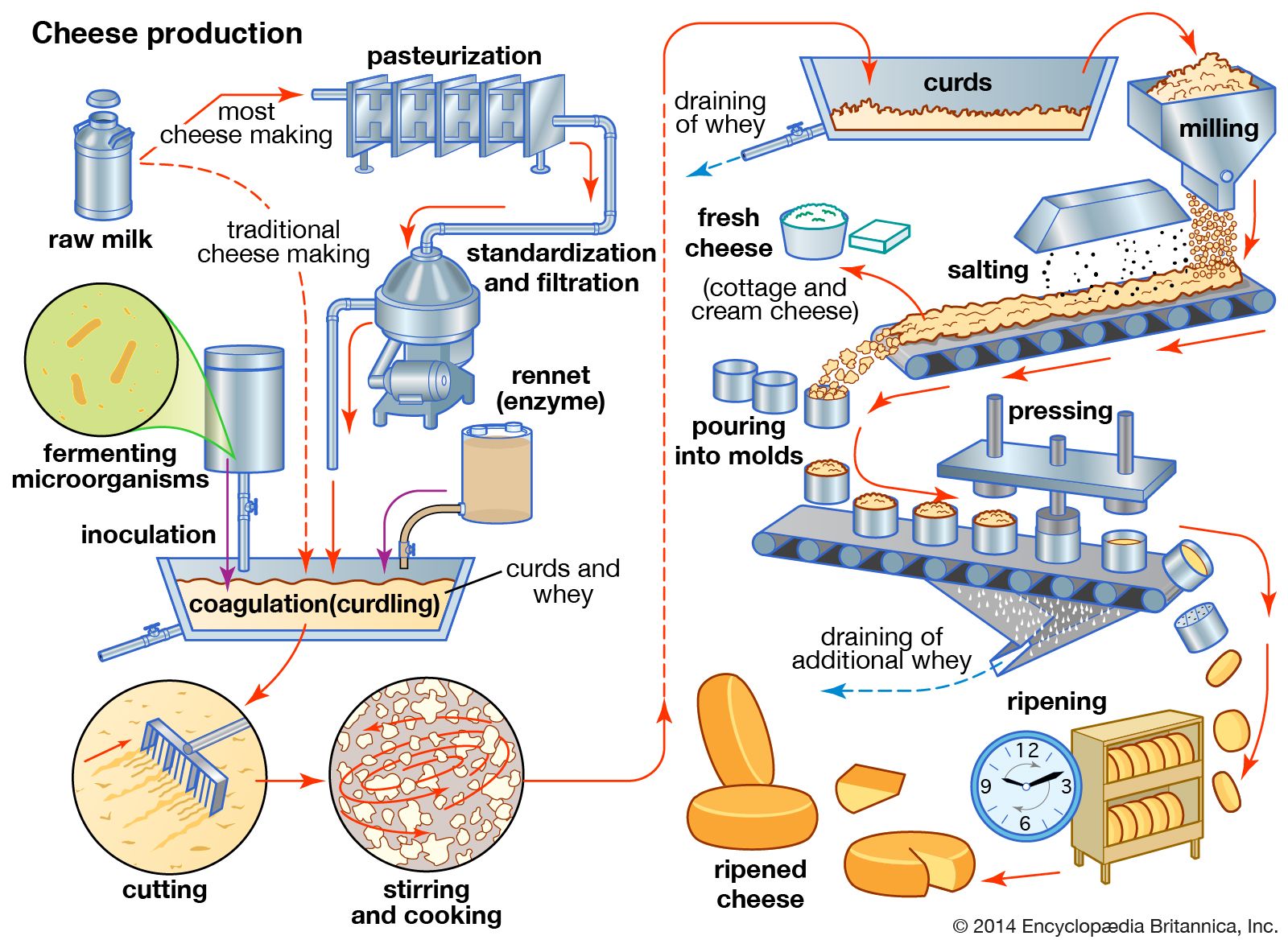

The process of making cheese involves several key steps, which have been refined over centuries. Here is a detailed overview of the typical steps involved in cheese-making:

1. Milk Selection and Preparation

The first step in cheese-making is choosing the type of milk to use. Cheese can be made from cow, goat, sheep, or even buffalo milk. The quality of the milk is crucial for the flavor and texture of the final cheese. The milk must be fresh and of high quality.

Preparation:

- The milk is usually pasteurized to kill any harmful bacteria, although some artisanal cheeses are made from raw milk.

- The milk is then heated to the optimal temperature, usually around 30°C to 32°C (86°F to 90°F), depending on the type of cheese.

2. Adding Starter Culture

Starter cultures are bacteria that help acidify the milk and begin the fermentation process. These bacteria break down lactose (milk sugar) into lactic acid, which lowers the pH of the milk. This is an essential step for curd formation.

- The bacteria cultures are added to the milk and mixed thoroughly. These cultures will also contribute to the flavor and texture of the cheese.

3. Coagulation (Curdling the Milk)

The next step is to coagulate the milk, turning it into curds and whey. This is done by adding rennet, which contains enzymes that help the milk proteins (casein) to coagulate and form curds.

- Rennet is typically derived from the stomach lining of young animals, but vegetarian or microbial rennet alternatives are also available.

- The rennet is mixed with the milk, and the mixture is allowed to sit undisturbed for about 30 minutes to an hour, during which the curds form.

4. Cutting the Curds

Once the milk has set and curds have formed, they need to be cut to help them release the whey (the liquid part of the milk).

- The curds are cut into small pieces using a curd cutter or a knife. The size of the curds can affect the texture of the cheese; smaller curds generally result in a firmer cheese.

- Cutting the curds increases the surface area, allowing more whey to be expelled.

5. Cooking and Stirring the Curds

After cutting, the curds are gently heated while being stirred. This helps expel more whey and also affects the texture of the cheese.

- The temperature is gradually raised to about 38°C to 42°C (100°F to 108°F) depending on the type of cheese. Some cheeses require higher temperatures, while others are made at lower temperatures.

- The curds are stirred to prevent them from sticking together and to encourage even cooking.

6. Draining the Whey

Once the curds have reached the desired texture, the whey must be drained off. The curds are separated from the whey using a fine mesh cloth or a colander.

- The whey can be discarded or used for other purposes, such as in animal feed or for making ricotta cheese.

7. Pressing the Curds

The curds are then placed into a mold, and pressure is applied to help them further expel any remaining whey and compact the curds into a solid mass.

- The pressing process can vary in duration and intensity depending on the type of cheese being made. For example, softer cheeses like Brie are pressed lightly, while harder cheeses like Cheddar are pressed more heavily.

- The cheese is typically pressed for several hours, and the weight is gradually increased as the curds consolidate.

8. Salting the Cheese

After pressing, the cheese is salted. Salt serves several purposes: it enhances flavor, helps control the growth of bacteria, and aids in the cheese’s preservation.

Two Common Methods for Salting:

- Dry Salting: Salt is rubbed onto the surface of the cheese, or it is mixed into the curds before pressing.

- Brining: The cheese is soaked in a saltwater solution for a period of time.

The amount of salt used and the salting method can vary based on the type of cheese being made.

9. Aging (Curing or Maturing)

The next step is aging the cheese, also known as curing or maturing. During this stage, the cheese develops its full flavor and texture. Aging can take anywhere from a few days to several years, depending on the type of cheese.

- The cheese is stored in a controlled environment, such as a cheese cave or aging room, where temperature and humidity are carefully monitored.

- Throughout the aging process, the cheese may be turned, washed, or brushed to encourage the development of its rind and prevent unwanted mold growth.

- As cheese ages, the proteins and fats break down, leading to a more complex flavor profile. For example, cheeses like Cheddar and Gouda become sharper and more intense as they age, while cheeses like Brie or Camembert have a creamy texture even when young.

10. Finishing Touches

Once the cheese has reached the desired age, it is removed from the aging room and prepared for sale or consumption.

- Some cheeses are coated with wax, herbs, or spices, or they may be smoked to add additional flavors.

- The rind, which may be natural or artificial, forms around the cheese during aging and can range from thin and soft to thick and hard, depending on the cheese.

11. Packaging and Storing

After aging, cheese is packaged for sale or consumption. Packaging helps preserve the cheese and protect it from contamination.

- Cheese may be vacuum-packed, wrapped in paper or plastic, or stored in a wax coating.

- It is important to store cheese at the appropriate temperature and humidity to ensure it stays fresh and maintains its flavor.

Types of Cheese and Variations

The final characteristics of cheese, such as texture, flavor, and appearance, depend on the type of milk used, the bacterial cultures added, the method of curdling, the pressing technique, and the length and conditions of aging.

There are countless varieties of cheese, ranging from soft cheeses like Brie and Ricotta to hard cheeses like Parmesan and Gouda.

Conclusion

Cheese-making is a complex and delicate process that combines both art and science. Each step—starting with the selection of milk and ending with aging—contributes to the unique characteristics of the cheese. Whether making cheese at home or on an industrial scale, the fundamental principles remain the same, though the techniques and conditions can vary widely based on the type of cheese being produced.